Comprint prides itself on its retained industry and process knowledge, and offers a comprehensive engineering design service to provide the printing and converting industry with a complete "engineered solution" package, to address all processing problems.

Latest development of CTP1400 Sheeter for cutting valuable printed reel. HS1400 for paper converting industrial. Rotary hot foil stamping / diecutting production line with option rewind facility.

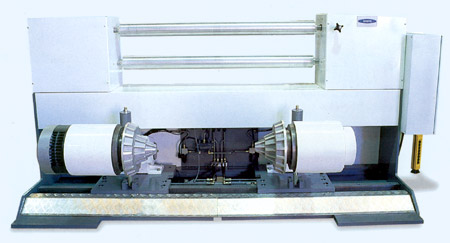

CTP 1400 Cut to Register Sheeting Machine

- Maximum web width: 1400mm

- Maximum speed: 300m/min

- Maximum knife load: 600gsm

- Cutting accuracy:+/- 0.1mm

- Maximum web width: 1400mm

- Maximum speed: 300m/min

- Maximum knife load: 600gsm

- Cutting accuracy: 0.5mm

Optional Accessories

- J Series Reel Stand

- Auto shaftless unwind CS1500

- 3 station slitting unit

- Individual high speed tape drive

- Beater roller

- Edge roll decurler

- Ribbon type trim waste removal system

- Web tension control

- Web guiding unit

- Vacuum tail arrest

- Layboy top tapes

- Knife air jets

- Static eliminator

- Cut to preprint system

- Buttom knife suction device

- Delivery top tapes

- Tape inserter

- Reject gate

- Non-stop delivery

- In-line with press

- Auto length and squareness control

|

|

|

Auto shaftless Unwind (CS 1500) |

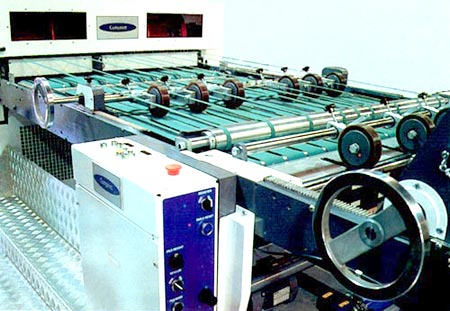

Forwarding Tape unit/Slow Down

Over Lapping Tape Unit |

|

|

| CTP Model |

3 Station Slitting Unit |

|

|

|

Vacuum Tail Arrest Unit |

|

||||||||||||||||||||||

Gravure Series:

|

|

G 1000 Gravure Press (Film/Paper) |

|

G5000 Gravure Printing Press

SPECIFICATION

|

Maximum web/printing width Minimum web width |

1060/1000mm 500mm |

|

Printing repeat range |

400-800mm |

UnwinderMaximum roll diameter Inside core diameter Direction of unwinding & splicing |

1500mm 150mm One directions |

Sheeting Specification:Cut-off range Cutting accuracy Maximum stacking height Maximum stacking weight |

500-1100mm infinitely variable + 0.1mm for register cut 1200mm 2 tons |

RewinderMaximum roll diameter Inside core diameter Direction of rewinding & splicing |

1000mm 76mm One direction |

|

Maximum Operating Speed Note: Print speeds are influenced by the type and quality of the substrates inks and solvents, and the printing design. |

300 metres/min |

| Typical material range:

Paper and Cardboard |

60gsm - 350gsm |

|

Tension range |

6 - 80kg |

|

Main drive (standard) - DC thyristor controlled |

38kW |

|

Drying System |

Electric with Recuperator heat recovery system. Other systems available upon request. |

|

| Description | ||

|

- The Comprint FG500 introduces a new concept to the printing of labels and flexible packaging.

|

||

- Maximum web width 500m

- Maximum unwind and rewind roll diameter 800mm

- Maximum operating speed 150m/min

- Printing repeat 250-500gsm

- Typical material range

- Polypropylene - OPP/BOPP

- Polyester

- Alumimum Foil

- Paper

- Composite laminates

|

Multiflex 1000 Wet and Dry Laminator

- Maximum coating width 1000mm

- Maximum mechanical speed 250m/min.

- Processing webs:

- Aluminium

- Paper

- Polyethylene

- OPP

- Polyester cellulose and a wide range of flexible packaging substrates

For more detail about the products, please click to www.comprint.com.hk